Expresso Mes®

Expresso

Mes®

Expresso Mes®software

controls industrial plant machinery

Expresso MES® (Manufacturing Execution System) is the software that manages data acquisition from industrial plant machines, machine status detection, production data recording and anomaly management, allowing monitoring, tracking and control of the entire production process in real time and with absolute precision.

Expresso MES® integrates with the customer’s ERPs, allowing complete control over production progress and can be installed on any PC or server, with a minimum commitment of resources.

The Expresso MES® software and the Expresso IoT 4.0.2 board, the hardware designed and manufactured by VM Vision, make up the Expresso MES® suite.

Machine States Collection

For each machine in the system, Expresso MES® records, in real time and with absolute precision:

- Machine downtime – reasons for downtime

- On the move – real-time production

- In maintenance – reasons for maintenance

- In alarm – recording of all alarms

Expresso MES® features

The Expresso MES® suite helps companies optimize the efficiency and productivity of their plants, improve preventive maintenance and reduce management costs by ensuring:

- Real-time monitoring of the number of pieces produced, to calculate the performance of the machinery and personnel for a specific WO (Work Order)

- the machine states (anomaly, in maintenance, in automatic, not active)

- the possibility for the operator to associate the cause of the stop for the detection of anomalies lasting more than 3 minutes (micro stop) in a simple way with the aid of a cordless barcode reader

- interfacing with the customer’s ERP, with frontier tables for production progress

- data recording with the Expresso Manutenzione® suite, which is thus completed by providing real MTBF and MTTR KPIs

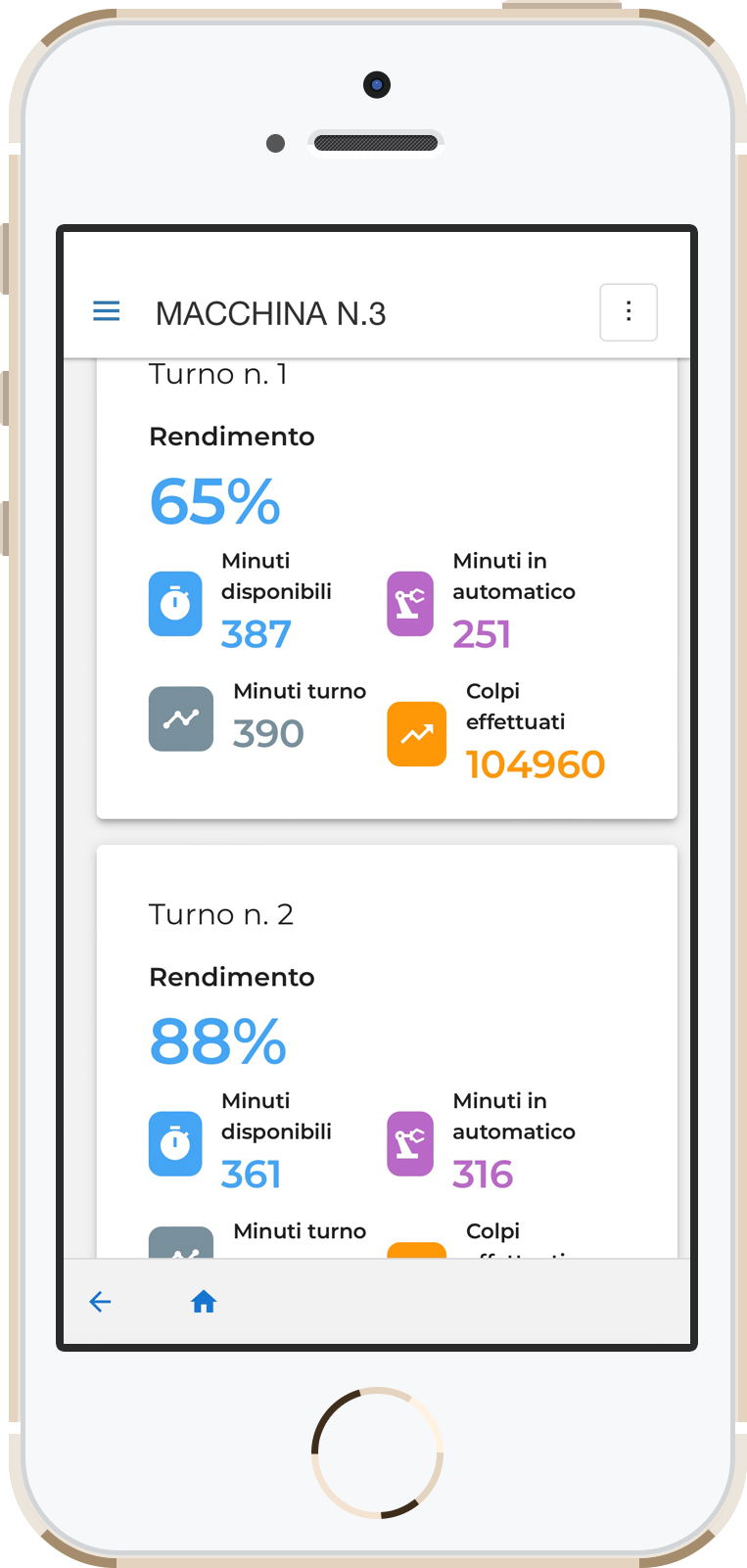

- real-time consultation of all acquired data on any device

The benefits of the Expresso MES® suite

- Greater production efficiency

By being able to monitor production in real time and detect any anomalies or downtime, operators can intervene promptly to minimize downtime and maximize production.

- Reduction of maintenance costs

Thanks to the recording of maintenance data and the possibility of calculating real MTBF and MTTR KPIs, it is possible to plan preventive maintenance interventions more accurately and reduce corrective maintenance costs.

- Improvement of product quality.

By exploiting the functionality that allows you to associate the causes of machine downtime, it is possible to identify any repetitive problems and intervene to improve the quality of the final product.

- Access data from anywhere

Thanks to the real-time consultation of the acquired data on any device, operators and production managers can monitor the progress of production from any place and at any time.

- Flexibility and scalability

Expresso MES® is designed to adapt to the needs of different types of production plants and can be easily scaled according to the needs of the company.

- Greater data security

The Hardware/Software combination allows you to store data on an SD in case of Wi-Fi connection failure, ensuring data security even in case of problems with the company network.

The technical aspects of Expresso MES®

- connection to IoT 4.0.2 board

- connection to Siemens PLC and Ethernet PLC with Modbus/OPC UA protocol

- Fanuc numerical control connection

- connection to proprietary machine softwares

- data collection from Advantech boards or I/O modules

- data collection from the plants’ supervision software

- data exchange of configuration files within the PLC

- sending digital signals from the machine to the IOT

- responsive Web Software module, accessible from smartphones, tablets or multi-platform computers