Trace 4.0 ®

Trace 4.0 ®

The Trace 4.0 ® software is mainly aimed at the industrial sector, mechanical and automotive companies, and allows real-time monitoring of all the stations that make up the plant.

Trace 4.0 ® allows you to monitor the processing and testing parameters of each individual product and record them for timely traceability. Trace 4.0 connects to the majority of commercial PLCs with MODBUS or Siemens protocol.

Trace 4.0® software features

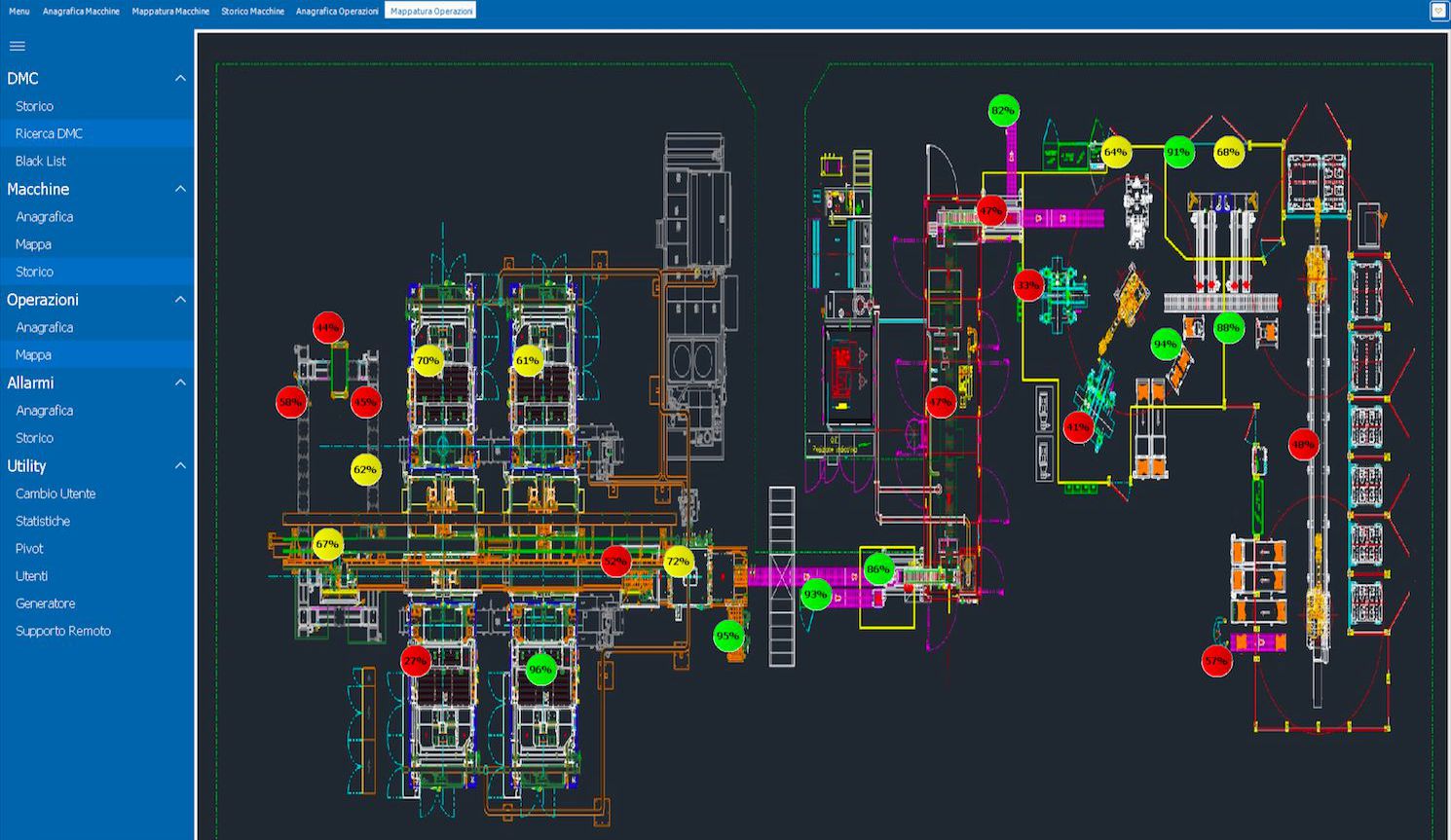

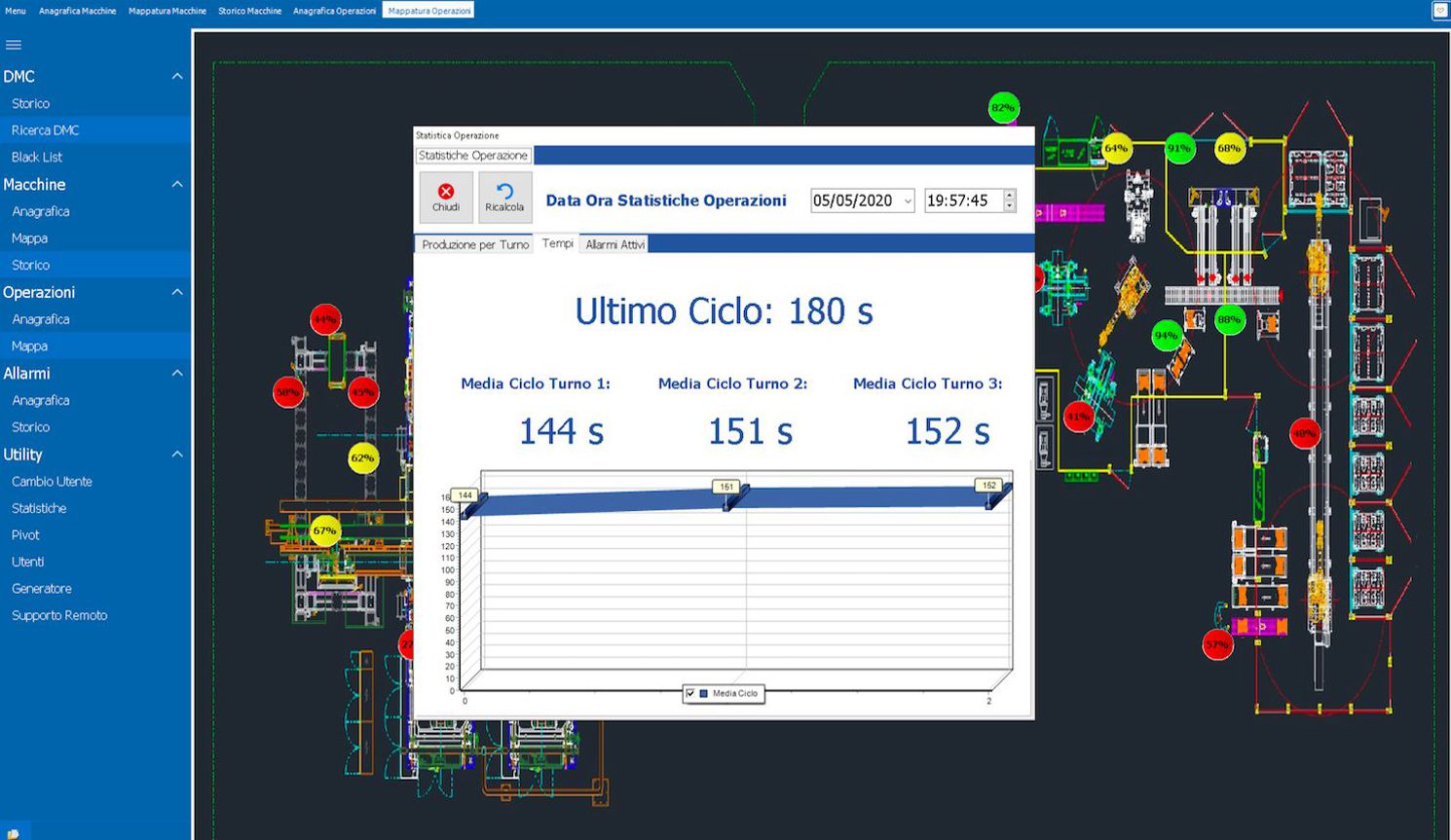

- Mapping of all the machines in the plant

- Register of all the machines in the plant

- Machine status history (Automatic, Excluded, In Failure, Under Maintenance)

- Operations master data, which can be associated with the machine and definition of the statuses for each operation (Good Piece, Reject Reasons and, for reject reasons, definition of the reject family, whether definitive or recoverable)

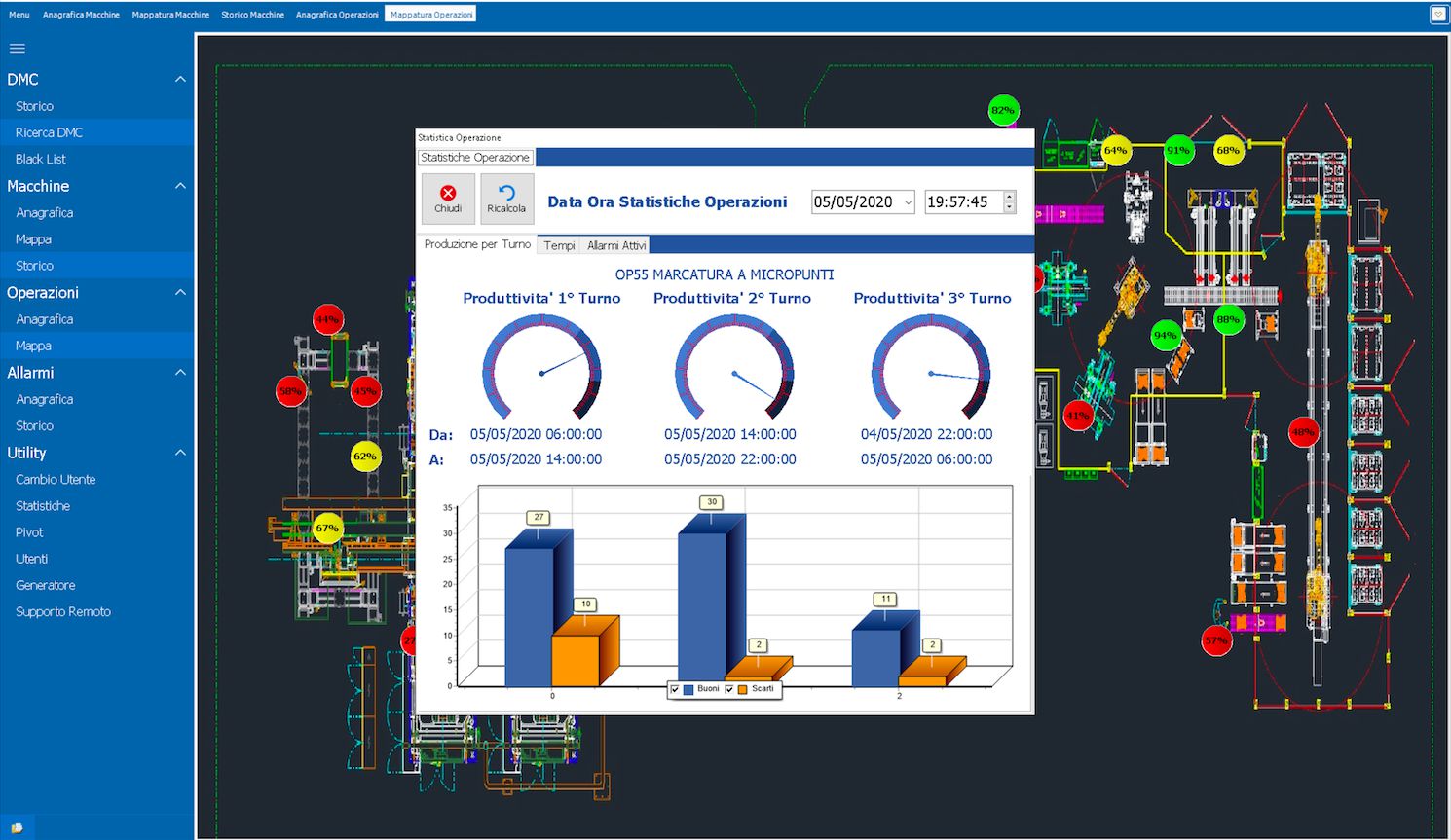

- Operations Map (real-time productivity per shift, average times per shift, active alarms per operation)

- Alarms register, which can be associated with the operation

- Alarm history for each individual machine

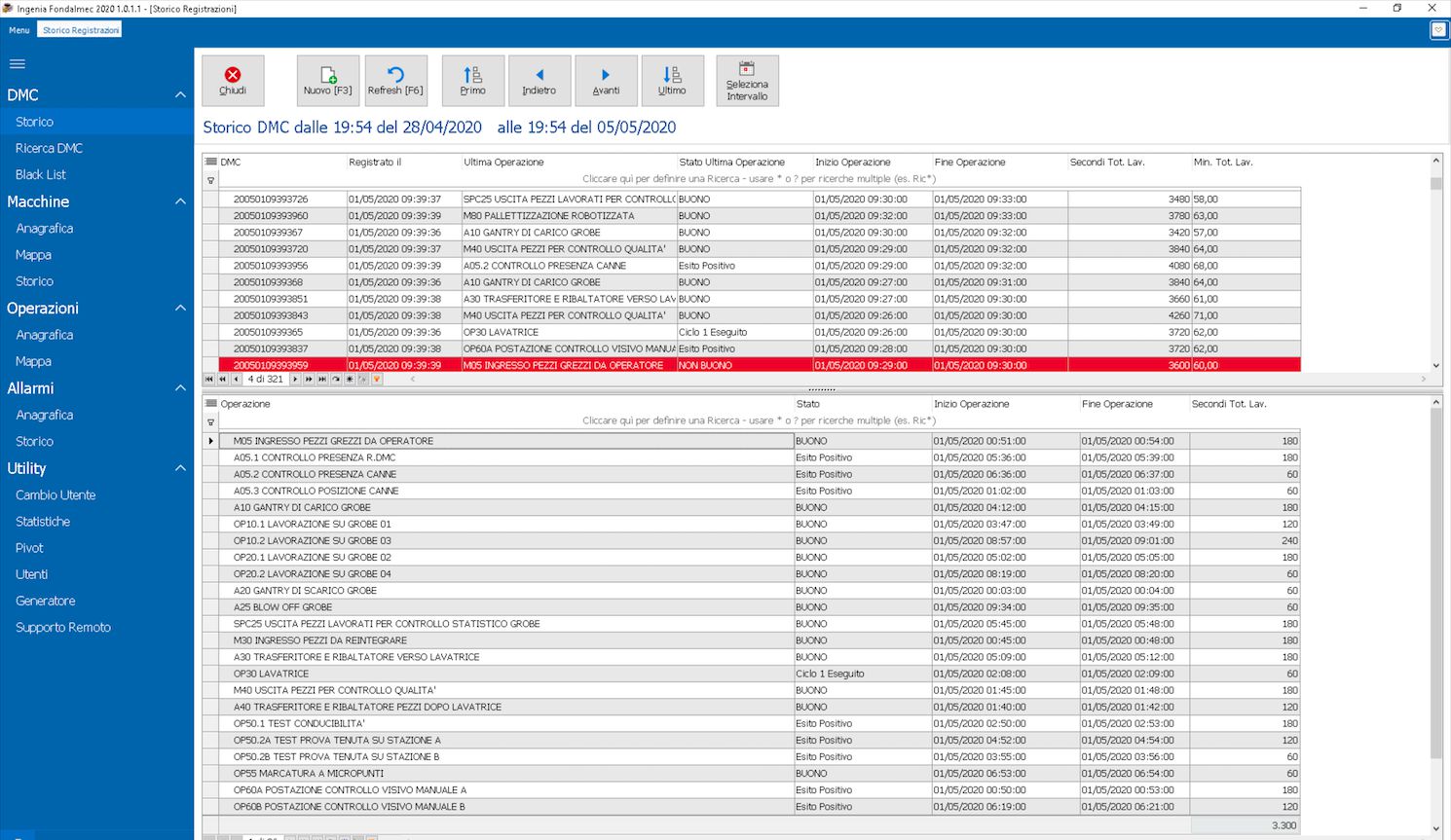

- Production History, with details of recorded operations and waste records

- User profile, with the possibility of managing authorizations per screen

- Pivot, with the ability to cross-reference search terms

- Standard Statistics

- Operator/Machine Interface

- Print or export all grids with Excel XLSX or XSL, HTML, XML files

- Remote Support