RTLS

VM Vision is at the forefront in the design of RTLS systems for the industrial and logistics sectors and is among the few software houses that can boast the creation of systems with the Real Time Locating System.

What is the RTLS system?

Real Time Locating System is the system that allows you to identify and track in real time with great precision the positioning and movements of any object within a delimited environment.

The system works through Wi-Fi signals emitted at certain intervals by tags, data transmission devices, which are collected by receiving equipment, locators and gateways, which record automatically and in real time, through a triangulation operation, the exact position of the object associated with the tag. The data is sent to the ERP, WMS and MES company systems to allow traceability control and management in an efficient and timely manner.

What is the RTLS system for?

Position and movement monitoring ensures the optimization of a company’s logistics and production activities.

In logistics, it allows you to always know the movement and positioning of a material, of a pallet within a warehouse and therefore eliminates waste of time due to its search.

In production it allows you to track the assembly and mounting processes of the various components but also the movements of semi-finished and finished products and therefore optimizes the control and verification of each production phase.

The benefits of the RTLS system

- traceability and production history creation

- increased efficiency and productivity

- reduction of errors, times and production costs

- increased flexibility and production reactivity

- improved performance of production workers

- easy to use

- modularity and flexibility

- easily integrated and implemented

- economic

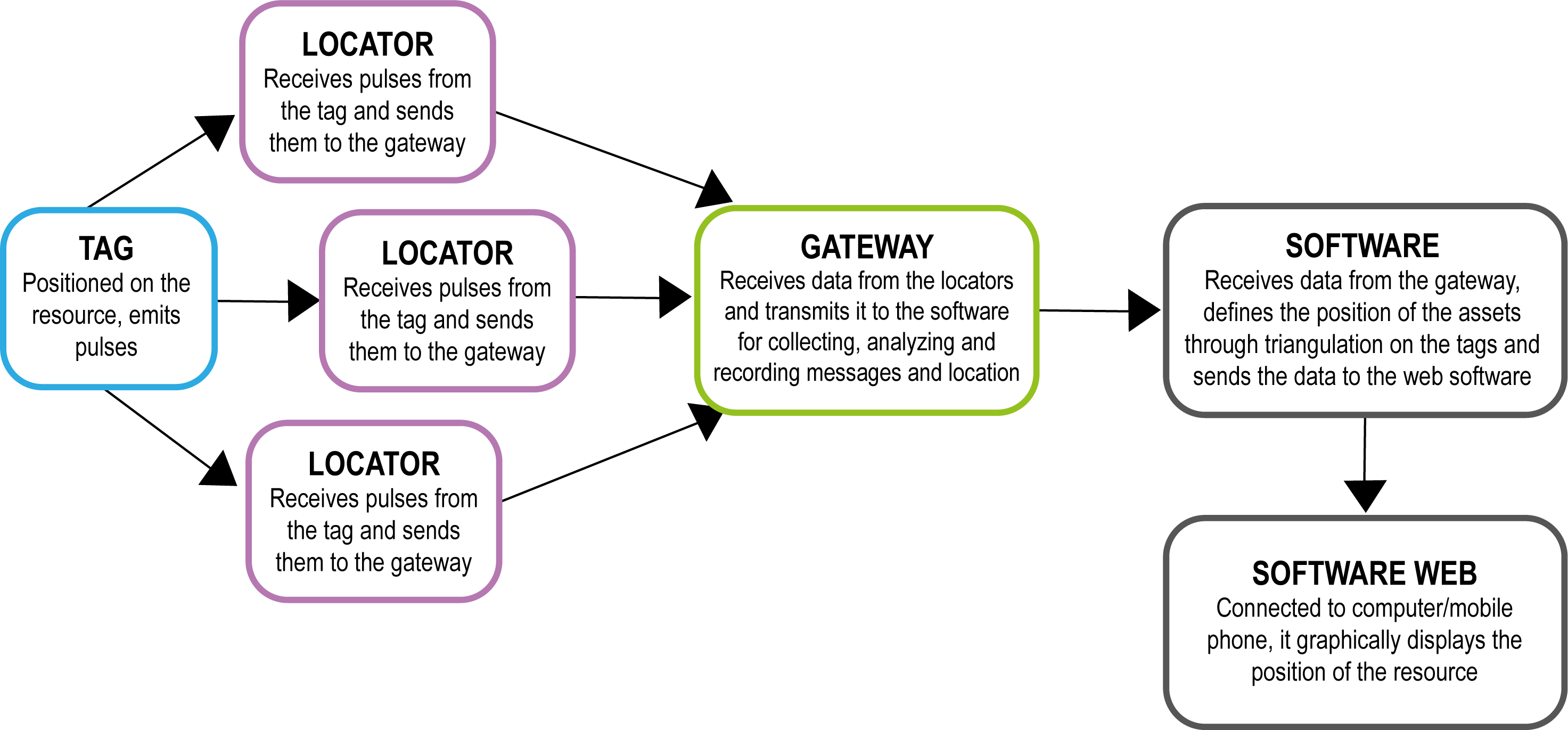

The elements of the RTLS system

Tag

Self-powered device that is placed on the asset to be tracked. The battery-powered tag emits pulses that are sent to the locators and forwarded to the gateway.

Locator

Devices installed in fixed points in the environment where the tags move. To track the movements it is necessary to install an average of 3 locators to cover the entire area using the triangulation technique.

Gateway

Fixed device that receives the messages emitted by the locators and sends them to the data collection software. Each gateway, sure enough, records the strength of the signal emitted by the tag towards each locator.

Data processing software

Receives and analyzes the messages sent by the gateway, processes them in real time, records the instant position of the tag and sends it to the web software creating a historical archive of the movements.

Web software

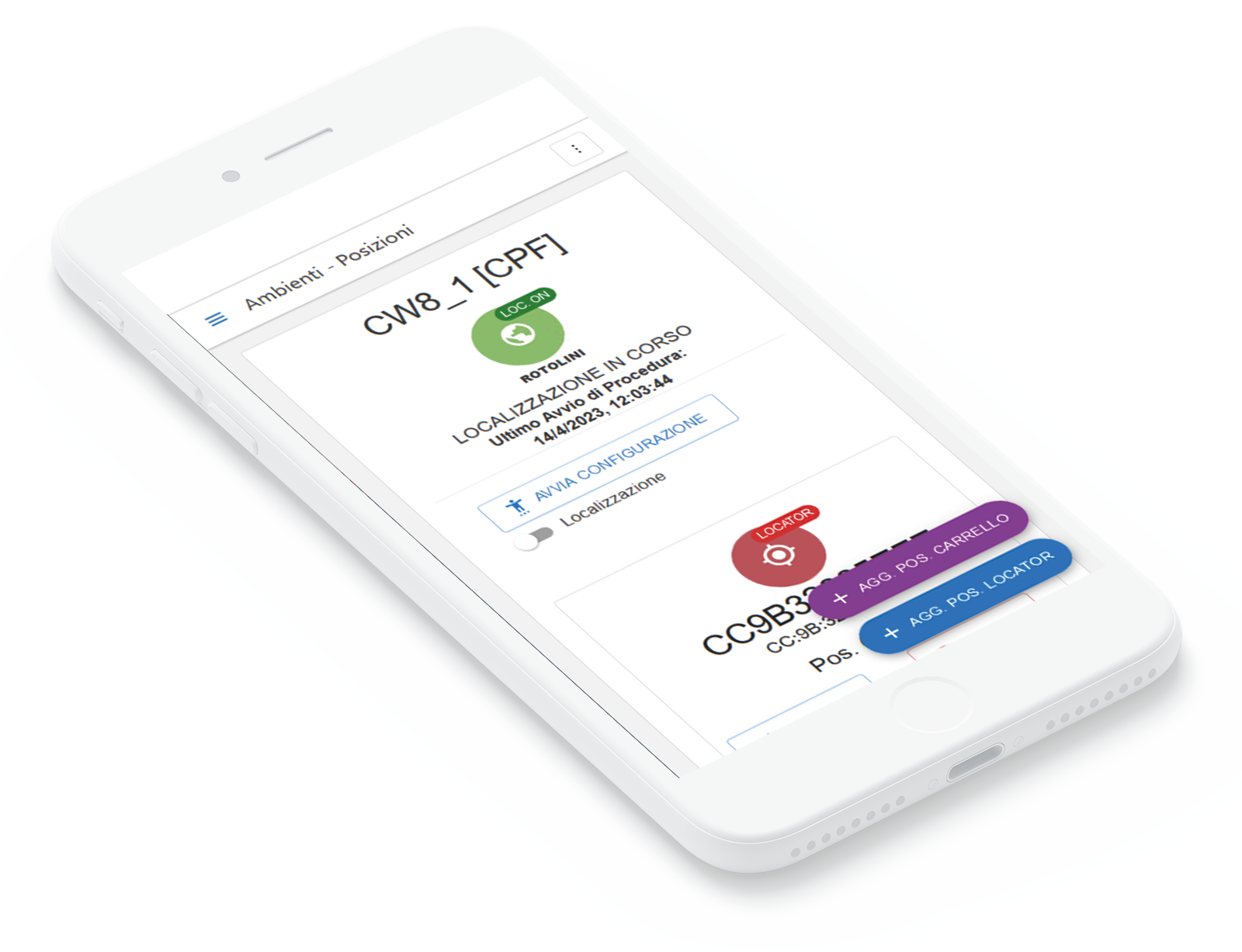

Responsive, allows the consultation and graphical display of data on PC, tablet or smartphone.

How the RTLS system works

RTLS system technologies

RTLS systems can use two different tag types:

- BLE Tag, Bluetooth Low Energy

- UWB Tag, Ultra Wide Band

In summary, here is a comparison between the two tags:

| BLE Tag | UWB Tag | |

|---|---|---|

| Price | 20 – 25 € | 60 – 80 € |

| Battery life | 2 years | 3 months |

| Accuracy | 1-5 m | 10 cm |

The technology selected by VM Vision

VM Vision uses BLE technology with active RFID Tags because, compared to UWB technology, it guarantees important advantages:

- Greater energy efficiency

- Lower precision and accuracy

- Increased data transmission times

- Simple configuration and implementation

- Lower system installation and hardware costs

To overcome the lower precision and accuracy of BLE technology, VM Vision has developed the VManage 4.0 data acquisition software.

VManage 4.0, the software made in VM Vision

VManage 4.0 is the data acquisition software specific for the RTLS system, developed to meet the needs of companies looking for an efficient solution to track in real time the position and movements of their resources within the corporate environment.

VManage 4.0 is designed to take advantage of BLE technology, ensuring positioning accuracy and precision ranging from 50 cm to 1 m.

The software features an intuitive dashboard, which displays all monitored assets, tag inventory, battery charge percentage of each tag, and movement history of monitored assets.

Having real-time tracking of the positioning and movements of resources at any time allows you to optimize the efficiency of the production cycle.

How a VM Vision RTLS system is born

- VM Vision technicians carry out an initial investigation in the company with the aim of defining the locations of the production lines to be traced.

- Signal analysis tests are performed to define the positioning of the different gateways to cover the areas to be monitored. Gateways positioned on telescopic rods are used and distances are recorded with laser meters.

- Once the positioning of the gateways has been defined, the database on the server is configured.

- Tags are placed and configured, gateways are installed, and location tests of tracked assets are performed.

- A final acceptance test is carried out to ensure the correct functioning of the system.

- The system is validated, becomes fully operational and begins its work of tracking resources.

VM Vision creates and markets

custom software and integrated hardware for RTLS technology

and is always available to provide any clarification

and support the customer in defining the system most suitable for them.