THE CLIENT

Bertolotto Porte is the point of reference for Made in Italy design and style of interior doors.

THE SOLUTION

1 In 2010, a first project began to label individual doors and record production in the various phases. A series of automatic applicators and manual labelling stations are installed, scanners are inserted and software for recording the phases is developed.

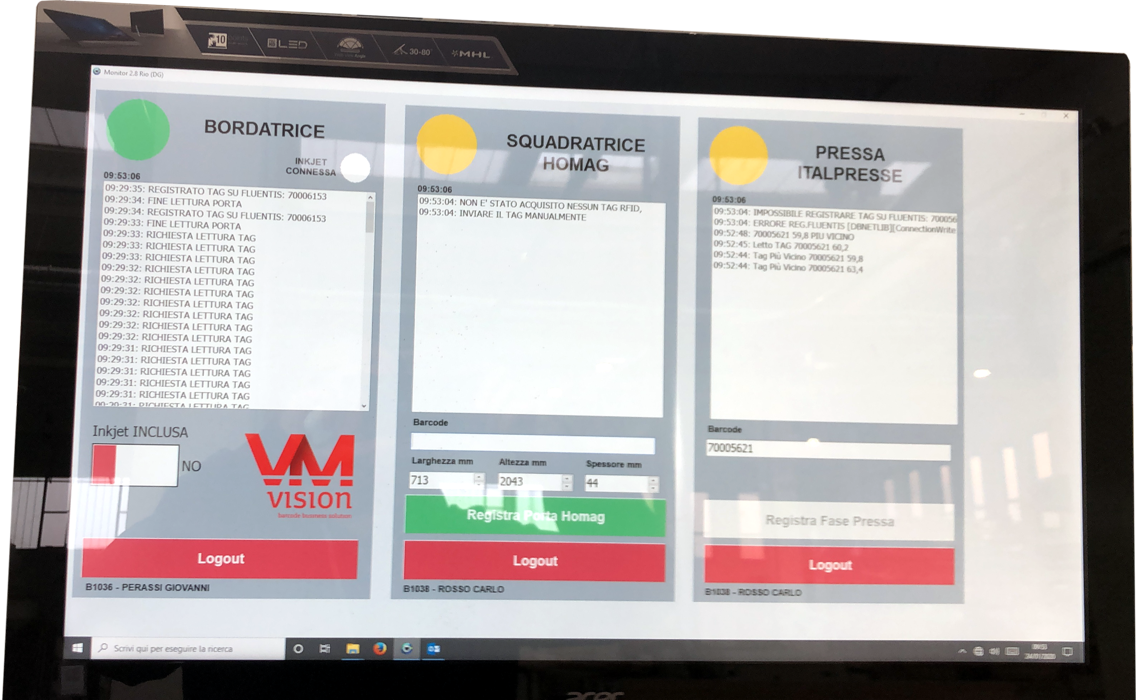

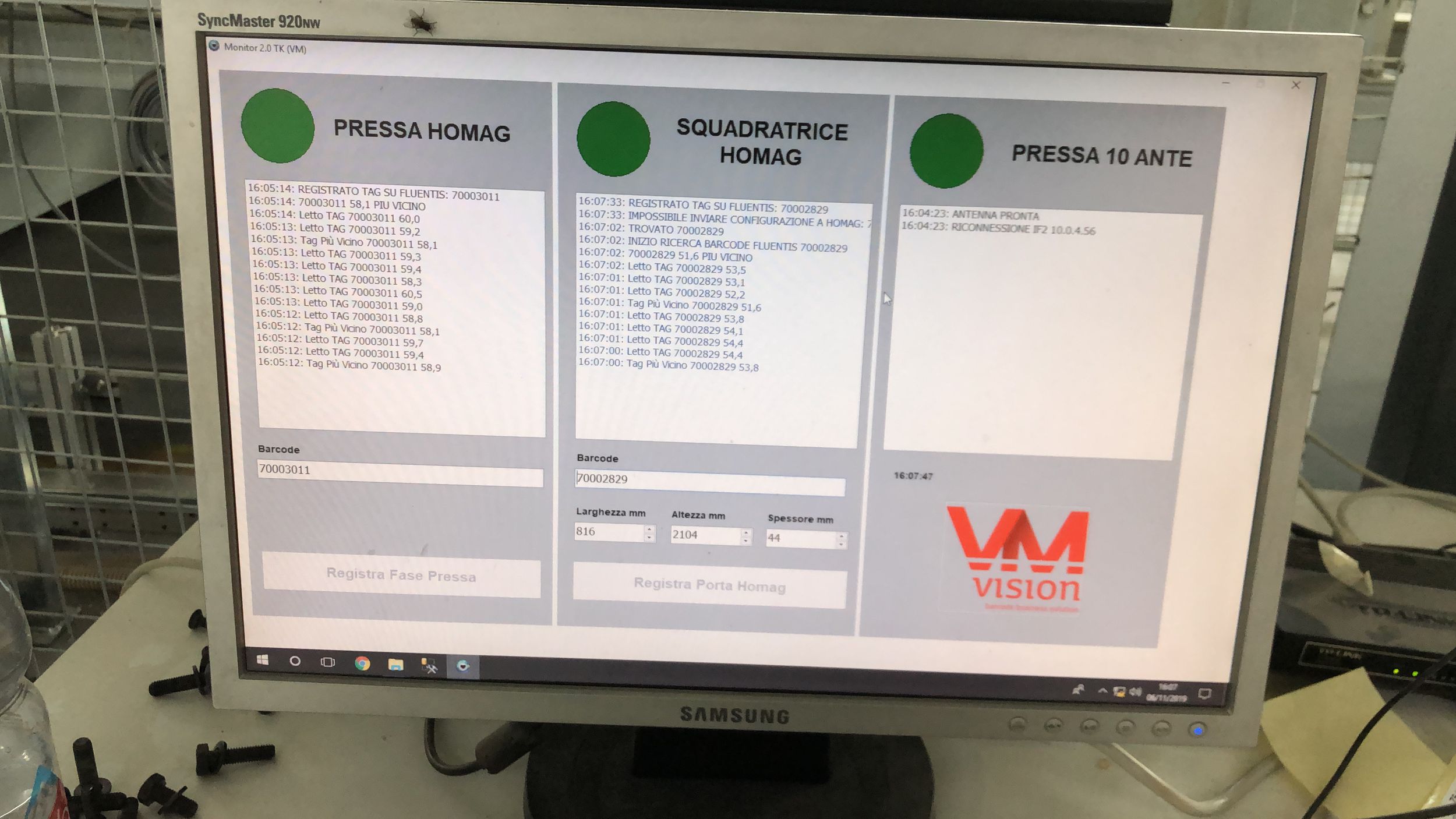

2 As the work proceeds, the Client also requests integration between the company configurator and the management of machines produced by different manufacturers. A series of software is born that, by reading the barcode of the door, translates the configurator data into recipes with which the stations that make up the production process are managed and coordinated.

3 Subsequently, shipments are also managed via handheld devices, packaging lines, production lines and everything necessary for the progress of production and shipment.

4 In 2019 the Client makes a huge investment and chooses to equip itself with new technology, switching from using Barcode Labels to RFID Labels. The entire factory is transformed with the insertion of new production lines, and with the complete RFID management of all movements with the use of printers, readers, antennas and Android palmtops, completely managed by our software.